Job Description

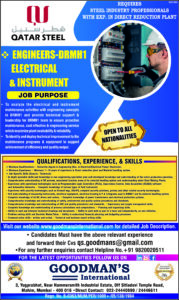

Position Title: ENGINEER – DRMH1 ELECTRICAL & INSTRUMENT –

(EXPERIENCE IN DIRECT REDUCTION PLANT)

Reports to: HEAD OF SECTION

Division: Operation

Department: Maintenance

JOB PURPOSE:

To analyze the electrical and instrument maintenance activities with engineering concepts in DRMH1 and provide technical support & leadership for DRMH1 team to ensure proactive maintenance, cost effective & engineering service which maximize plant availability & reliability. To identify and deploy technical improvement to the maintenance programs and equipment to support achievement of efficiency and quality output.

KEY ACCOUNTABILITIES:

Technical Maintenance Activities

- Analyze the daily maintenance activities from the daily log books and record sheets versus the plan and make any required modifications to subsequent daily plans in order to support the achievement of the maintenance plans.

- Analyze the calibration and maintenance result sheet, identify, design and propose to management technical maintenance improvements and/or equipment developments in order to support the continual technical improvement of maintenance provision.

- Identifying and addressing technical problems with implementing solutions for rectification.

- Conducting technical research and applying new knowledge.

- Study and review engineering designs for new projects and identify the variations

- Prepare Tender documents for CAPEX projects, evaluate the Technical Offers, schedule the project timeline and cash flow, coordinate with internal and external parties for execution, monitor the progress and confirm the project completion according to the approved schedule.

- Interact daily with the operation team to interpret their needs and requirements and represent them in the field.

- Carry out and supervise all maintenance programs for critical and/or complex plant equipment including all types of Automation Systems in order to ensure that continuous plant availability and equipment downtime is minimized.

- Confirm execution of all maintenance program (Preventive, Predictive, Breakdown) with the plant /shift supervisor in order to ensure the achievement of high standards of plant and equipment operation with minimal production downtime

- Communicate and co-ordinate with vendors, technology suppliers & third parties for all plant know-how issues, troubles, upgrading & modifications in order to ensure that maintenance provision meets the ongoing needs of the production process.

- Identify and recommend equipment / systems for procurement, provide technical specification, perform technical evaluation of equipment and suppliers and ensure effective commissioning and follow up where appropriate.

- Manage discrete projects and support / contribute to larger projects, e.g. internal expansion, from feasibility study through to implementation in order to ensure that projects are delivered to time, cost and quality standards

- Apply engineering technical knowledge and skills in electrical and instrument in various aspects of applications

Planning

- Estimating costs of Annual OPEX and CAPEX Budget and timelines for projects execution.

- Prepare maintenance annual plans activity in order to ensure the achievement of high standards of plant and equipment operation with minimal production downtime.

- Plan, identify and recommend equipment / systems /spares for procurement, provide technical specification, perform technical evaluation of equipment and suppliers and ensure effective commissioning and follow up where appropriate.

- Prepare long term maintenance plan for own area, for management approval, in order to ensure that plant and equipment maintenance needs are met and production process availability optimized for the coming 5 years.

Budgeting & Inventory Control

- Prepare and propose annual budget OPEX /CAPEX figures for management approval that accurately represent anticipated costs and enable effective cost management

- Monthly review for the budget consumption figures for electrical and instrument to be in line with the approved budget consumption plan.

- Control the record management systems to manage inventory holding including its costs and to ensure that minimum stock is available all the time without unnecessary duplication.

- Review the monthly shift schedule plan to ensure the overtime within the approved budget .

Supporting Activities

- Support IT cyber security team in monitoring and controlling the OT cyber security.

- Support and provide guidance to his team in technical studies to contribute to ongoing development of maintenance and operation activities to ensure the technical problems are effectively resolved.

- Support management in achieving the targets of company corporate objective such as safety, profitability and sustainability.

- Conduct on the job training, demonstration and instruction for new and/or existing employees in order to support their professional development and ensure the highest standards of performance are achieved across the shift team.

Data Recording and Analysis

- Periodical review of inspection results and perform data analysis to predict the expected troubles and ensure that plant and equipment data is available and well analysed.

- Ensure all the data records follow relevant certifications such as ISO-9001, 14001, 45001 etc.

Reporting

- Prepares the reports to management with the data analysis and recommendations to achieve the best performance in all manners.

- Report technical abnormalities with recommendations to the management in order to ensure senior management have sufficient information to support decision making and giving direction for appropriate remedial action and / or planning of future maintenance activity.

- Review of delays and fault reports for root cause analysis corrective actions

Continuous Improvement

- Staying up to date with international engineering trends.

- Identify and develop improvements to operating standards, policies, and procedures to support continuous improvements in operating performance.

- Lead and promote technical development in equipment and process maintenance in order to ensure continuous improvement in operation and achieving maintenance KPIs.

Health, Safety & Environment

- Identifying hazardous situations and evaluate the relevant risk in order to conclude appropriate action to maintain safe working environment.

- Confirm compliance with all relevant safety, health and environmental procedures and raise any of HSE concerns and incidents to HSE with the recommended actions to ensure safe work practices and environment and to achieve corporate Zero Incident Objectives.

- Continuously review operating and safety standards and procedures (HIRA/PTW/LOTO/TBT . . . etc) in DRMH1 area, updating and modifying as appropriate under the direction of the Maintenance Engineer/Section Head

- Contribute in all PSM and HAZOP studies in DRMH1 plants.

- Prepare annual plan for monthly safety meeting and attend all safety patrols & meeting.

- Confirm implementation of planned safety training in time and take actions for the plan deviation in order to comply with the department objectives, the safety procedure and legal requirement trainings (HIRA/LOTO/PTW/Confined Space/Working At Hight/AGT/First Aid, . . . etc).

- Review the reported observations in the monthly safety activities in the department including HES safety patrol, MRM, fire drill and environment audit and confirm its closing action plan in order to ensure any HES operating issues are understood and appropriate corrective action is taken

Policies, Processes and Procedures:

- Monitor compliance to applicable codes, practices, QA/QC policies, performance standards and specifications

- Draft all Standard Operation Procedures for all maintenance activities in his area.

- Confirm the continuous process of reviewing the operating and safety standards and procedures, updating and modifying as appropriate under the direction of the Maintenance Section Head

- Identify and design system to ensure all operating, safety, environment, and quality procedures are followed to ensure the highest standards of operational integrity are achieved.

- Follows all relevant policies, processes, standard operating procedures and work instructions in the section so that work is carried out in a controlled and effective manner.

Related Assignments: Perform and carryout any additional assignment /tasks as required by management.

Context, Work environment & DECISION-MAKING AUTHORITY:

- The job holder is required to foresee and meet current and potential challenges presented by rapid operational and staff growth in creating and implementing effective operating and maintenance strategy.

- Key decisions having significant impact on operations section are referred to the line manager for approval before implementation.

QUALIFICATIONS, EXPERIENCE, & SKILLS:

Minimum Qualifications:

- University degree in Engineering (Bsc. in Electrical/Electrical Power/ Electronic)

Minimum Experience:

- Minimum 7~10 years of experience in Direct reduction plant and Material handling system

Job-Specific Skills (Generic / Technical):

- In depth specialist skills and knowledge in own engineering specialism plus well-developed knowledge and understanding of the entire production operation

- Comprehensive understanding of DR process, associated function areas of its material handling system and understanding whole Steel Making Plants.

- Experience with operational technologies such as Programmable Logic Controllers (PLCs), Supervisory Control, Data Acquisition (SCADA) software and Automation Networks.

- Experience with security technologies such as firewall logs, IDS/IPS, endpoint security solutions, proxies and other related security technologies.

- Full understanding of measuring instruments, electrical equipment, electrical drawing & P&I diagrams used in DRMH1 and its material handling system.

- Complete knowledge of AC/DC drives and motors

- Complete knowledge of power transformers and electrical protection systems

- Complete knowledge of various types of field instrument

- Comprehensive knowledge and understanding of safety, environment and quality system procedures and standards

- Comprehensive knowledge and understanding of HSE and quality procedures and standards.

- Complete Knowledge and understanding of process calculations and computations.

- Ability to read and interpret technical drawings and documents.

- Supervisory and people management skills.

- Planning and organising skills.

- Ability to work both as part of a team and independently, on own initiative.

- Problem solving skills and Decision Maker/Taker

- Ability to understand financial planning and budgeting processes.

- Communication skills – written and verbal.

- Technical and business report writing skills.

CORE COMPETENCIES:

- Creativity and Innovation: Generating viable, new approaches and solutions.

- Work Ethics and Values: Demonstrating and supporting the organization’s ethics and values.

- § Teamwork: Working collaboratively with others to achieve organizational goals

- Concern for Safety: Identifying hazardous or potentially hazardous situations and taking appropriate action to maintain a safe environment for self and others.

JOB FAMILY COMPETENCIES:

- Technology Design: Knowledge and application of engineering principles and techniques in the design, operation and repair/maintenance of machines, tools, and other equipment.

- Quality Control and Troubleshooting: Conducting tests and inspections of equipment and systems to evaluate quality or performance and addressing problems and deficits.

Fostering Communication: Listening and communicating openly, honestly, and respectfully with different audiences, promoting dialogue and building consensus.

Managing Resources: Understanding and managing available resources (Human, Plant & Equipment, Capital and Intangible assets)

Maintenance Planning and Scheduling: Demonstrates skills, knowledge, techniques, theory and methods in regards to meeting maintenance planning requirements

- Electrical/Electronics Engineering: Translates knowledge of the theory, concepts and principles underlining electrical/electronics engineering (field theory, analog electronics, computer aided design of circuits and control theory) in designing, developing, operating and testing electrical and electronic equipment, components or systems.

- Root Cause Analysis (RCA): Outlines details of the technical requirements and abilities to solve problems by understanding the problem’s real root causes, improves plant performance and stops problems by applying root cause analysis techniques.

High Voltage Systems Engineering: Applies knowledge of the inherent principles of electrical engineering and equipment in testing and operating equipment and conductors that carry current at transmission line-voltage.

-

Forward CV’s to qs.goodmans@gmail.com

HELPLINE NUMBER: +91-9820020511 / Landline N0: +91-24446677 /11