Job Description

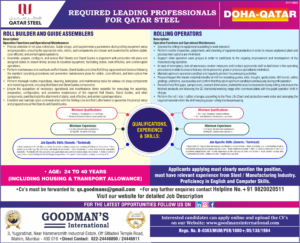

# ROLL BUILDER & GUIDE ASSEMBLER

JOB PURPOSE: To efficiently prepare, maintain and oversee the Roll Shop equipment, devices, and internal/ external offline operational and maintenance functions and processes to meet the operative and preventive maintenance plans and offline/ online preparation targets with high-quality work and minimal costs.

KEY ACCONTABILITIES:

Description

Operative Functions and Operational Maintenance

- Precise selection of roll pass schedules, Guide setups, and supplementary parameters during rolling equipment setup and preparation, ensuring the appropriate rolls, rollers, and components are chosen and assembled to achieve stable, cost-efficient, and uninterrupted operations.

- Assemble, prepare, configure, and assess Roll Stands and Stand Guides in alignment with production roll plans and assigned duties to ensure timely access to essential equipment, facilitating stable, cost-effective, and uninterrupted operations.

- Perform maintenance and overhauls on Roll Stands, Stand Guides and other Roll Shop equipment and devices following the standard operating procedures and preventive maintenance plans for stable, cost-efficient, and interruption-free operations.

- Perform thorough routine inspections, cleaning, lubrication, and maintenance tasks for various roll shop components and related equipment, including Roll Stand and Stand Guides components.

- Ensure the acquisition of necessary operational and maintenance items essential for executing the assembly, preparation, configuration, and preventive maintenance of the required Roll Stands, Stand Guides, and other components, contributing to the attainment of stable, cost-effective, and uninterrupted operations.

- Establish and maintain open communication with the Rolling Line and Roll Lathe teams to guarantee the prompt setup and preparedness of Roll Stands and Stand Guides.

Policies, Processes and Procedures

- Adhere to sectional policies, departmental procedures, relevant Standard Operating Procedures (SOPs) in daily activities, and actively participate in SOP workshops while contributing to the Job Cycles Checks (JCC) process for precise SOP updates.

Safety, Health and Environment

- Adhere to all applicable safety, quality, and environmental management policies, procedures, and protocols in order to uphold and maintain a healthy, secure, and environmentally responsible workplace.

Other Assignments

- Perform other related duties or assignments as directed by supervisor.

QUALIFICATIONS, EXPERIENCE, & SKILLS:

Minimum Qualifications:

- Technical / Vocational school certificate.

- Technical Diploma in relevant area is preferred.

Minimum Experience:

- 2-3 years relevant work experience in Rolling Mill line and/or Roll Shop.

Job-Specific Skills (Generic / Technical):

- Basic knowledge in Roll Building and Guide Assembly, including a broad understanding of Rolling Line Operations.

- Basic knowledge in metrology, fits, tolerances, and hands-on experience.

- Basic knowledge of safety, environmental, and quality standards.

- Familiarity with roll pass schedules, guide tabulations, and technical drawings interpretation.

- Ability to work in a team environment and independently with frequent supervision.

- Adequate English speaking, reading, and writing skills.

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————–

# ROLLING OPERATORS

JOB PURPOSE:To operate and monitor rolling mills equipment, plant and processes in order to support the achievement of the production plan through the timely production of conforming finished product through optimized condition

KEY ACCOUNT ABILITIES:

Description

Operative Functions and Operational Maintenance

- Operate the rolling line equipment according to work standard.

- Perform routine inspection, adjustment, and checking of equipment/production in order to ensure unplanned plant and process interruptions are minimized.

- Support other operation work groups in order to contribute to the ongoing improvement and development of the manufacturing operation.

- In case of emergency, take all necessary counter measures and contact appropriate staff as laid down in the operating procedures in order to ensure that any risk to personnel, plant or process operation is minimized.

- Maintain optimum operation condition and regularly perform housekeeping activities

- Prepare/Inspect the stands installed/standby at mill line including guides, rolls, troughs, guide plates, Mill tunnel, safety gratings, platforms, accessories and confirm that they are in optimum condition continuously during mill operation.

- Record/check Roll gaps, sample sizes, product dimensions, material tension/compression during rolling and ensure the finished products are following the QC standards/working range after communication with the pulpit operator/ shift in charge.

- Perform the roll / size / caliber changes according to the Pass Life Chart and production work order and arranging the required material within the shift keeping proper rolling line housekeeping.

Policies, Processes and Procedures

- Adhere to sectional policies, departmental procedures, relevant Standard Operating Procedures (SOPs) in daily activities, and actively participate in SOP workshops while contributing to the Job Cycles Checks (JCC) process for precise SOP updates.

Safety, Health and Environment

- Adhere to all applicable safety, quality, and environmental management policies, procedures, and protocols in order to uphold and maintain a healthy, secure, and environmentally responsible workplace.

Related Assignments

- Perform other related duties or assignments as directed by supervisor.

QUALIFICATIONS, EXPERIENCE, & SKILLS:

Minimum Qualifications:

- Technical / Vocational school certificate.

- Technical Diploma in relevant area is preferred.

Minimum Experience:

- Minimum 2-3 years relevant work experience in Rolling Mill plant/process operations

Job-Specific Skills (Generic / Technical):

- Basic understanding of plant and process specifications and parameters

- Basic knowledge and understanding of safety, environment and quality procedures and standards

- Basic mathematical skills

- Ability to work in a team environment and sometimes independently with minimal supervision as the task may be from time to time

- Basic problem solving skills

- Communication skills – written and verbal English language skills