Job Description

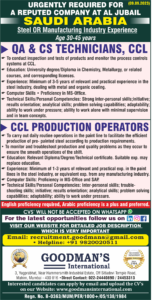

JOB TITLE : CCL PRODUCTION OPERATORS: ( CCL COATER OPERATOR / CCL ENTRY OPERATOR / CCL EXIT OPERATOR

DEPARTMENT OPERATIONS:(CCL)

DATE OF PREPARATION 2023

I. JOB PURPOSE

• To carry out daily routine operations in the paint line to facilitate the efficient production of prepainted steel according to production requirements.

• To monitor and troubleshoot production and quality problems as they occur to ensure the smooth operations of the shift.

II. GENERAL SPECIFICATIONS

Education

• Relevant Diploma/Degree/Technical certificate. Suitable experience may replace education.

Experience

• Minimum of 1-3 years of relevant and practical experience in the paint lines in the steel industry, or equivalent experience from any manufacturing industry.

Computer Skills

• Proficiency in MS-Office and SAP.

Technical Skills/Personal Competencies

• Inter-personal skills; trouble-shooting skills; initiative; results orientation; analytical skills; problem solving capabilities; adaptability;ability to work under pressure.

Languages

• English proficiency required; Arabic proficiency is a plus and preferred. Written and Verbal Communication Skills

• Average verbal and written communication skills.

Occupational Skills: Safety, Driving, Health, etc.

• Basic knowledge of international health and safety standards.

Others (If any) – Indicate any other requirements needed to perform the specific requirements of the job e.g. physical demands, requent travel, etc.)

• Physical exertion necessary to the position.

III. KEY RESULT AREAS (KRAs) and LIST OF RESPONSIBILITIES

KEY RESULT AREAS (KRAs)

(Identify the major areas or activities that will produce the contributions that the company expects from the

LIST OF JOB RESPONSIBILITIES

(Identify routine and non-routine functions the employee needs to perform to meet the identified KRA. As much as possible,highlight the result that is expected from each task)

LEVEL OF RESPONSIBILITY (Full, Partial, Supporting)

Paint Line Operations

• Receive from or hand over to previous/succeeding shift operator and identify equipment status, previous analysis, grade changes, paint thickness, roll quality, and finished goods quality.

• Conduct routine checks of the coater room on a regular basis, inspect assigned equipment, and check strip movement, roll quality, and paint levels on trays and drums to ensure a continuous flow of operations.

• Arrange paint according to production schedules in coordination with the Shift Foreman to ensure continuous processes.

• Maintain quality of production by ensuring all parameters are on target.

• Monitor and check paint level and viscosity and adjust as necessary.

• Follow up on product quality in the area of responsibility and inform the next level of supervision regarding any abnormalities.

• Monitor paint film thickness and roll condition and change as necessary.

• Make paint and roll changes as may be required by the production schedules.

• Clean paint trays, rolls, and pumps at start-up, shutdown, and during paint and roll changes.

• Push heavy barrels and bulky tow tanks of paint to transfer them to designated areas with the use of trolleys.

• Push heavy rolls to designated areas through the use of trolleys.

• Operation of Crane and Forklift required for the Paint Drum/Tank movement tasks.

• Partial

Documentation and Reporting

• Report any observed abnormalities regarding equipment to the next level of supervision for corresponding action and keep stand-by equipment in good working order.

• Record all necessary information such as paint or solvent consumption level and other reports in the Level 3 system and relay to the Shift Foreman at the end of the shift.Full

Safety and Housekeeping

• Comply with all safety and health policies and regulations.

• Follow established housekeeping rules, regulations, and procedures and keep all assigned

• Supporting equipment and areas of responsibility clean.

• Clear the work area of waste rags, solvents, and paints and ensure that paint and solvent containers are properly sealed and tagged before leaving the work area.

Other Functions

• All other necessary functions as may be deemed necessary and assigned by the next level of supervision.

-

Forward CV’s to recruitment.goodmans@gmail.com

HELPLINE NUMBER: +91-9820020511 / Landline N0: +91-24446677 /11