Job Description

| JOB TITLE

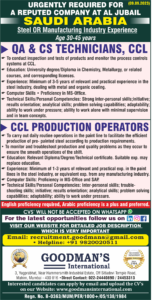

QA & CS TECHNICIAN, CCL |

DEPARTMENT

TECHNICAL SERVICES (QA & CS) |

DATE OF REPARATION

2023 |

I. JOB PURPOSE

- To conduct inspection and tests of products and monitor the process controls systems at

GENERAL SPECIFICATIONS

| Education | · University degree/Diploma in Chemistry, Metallurgy, or related courses, and corresponding licenses. |

| Experience | · Minimum of 2-4 years of relevant and practical experience in the steel industry, dealing with metal and organic coating. |

| Computer Skills | · Proficiency in MS-Office. |

| Technical Skills/Personal Competencies | · Strong inter-personal skills; initiative; results orientation; analytical skills; problem solving capabilities; adaptability; ability to work under pressure; ability to work alone with minimal supervision and in team concepts. |

| Languages | · English proficiency required; Arabic proficiency is a plus and preferred. |

| Written and Verbal Communication Skills | · Very good verbal and written communication skills.

· Ability to make and deliver reports and presentations. |

| Occupational Skills: Safety,

Driving, Health, etc. |

· Basic knowledge of international health and safety standards. |

| Others (If any) – Indicate any other requirements needed to perform the specific requirements of the job e.g. physical demands,

frequent travel, etc.) |

I. KEY RESULT AREAS (KRAs) and LIST OF RESPONSIBILITIES

| KEY RESULT AREAS (KRAs)

(Identify the major areas or activities that will produce the contributions that the company expects from the employee) |

LIST OF JOB RESPONSIBILITIES

(Identify routine and non-routine functions the employee needs to perform to meet the identified KRA. As much as possible, highlight the result that is expected from each task) |

LEVEL OF RESPONSIBILITY

(Full, Partial, Supporting |

| Operational Processes | · Monitor the process control parameters, such as levels in stages, temperature of oven and PMT, and other parameters relevant to the process. | · Partial |

| · Identify coils that do not meet requirements, put its processing on hold, and inform higher levels of supervision.

· Identify coils that meet requirements and advance to the next process stage. · Identify probable causes for deviations observed during processing and ensure its corrections in coordination with the Shift Foreman and other operators and technicians. · Verify accuracy of measuring instruments and report values beyond range to higher levels of supervision. |

· Full

· Full

· Partial

· Full |

|

| Testing and Inspection for Standards Compliance | · Conduct inspection of finished products for conformance to set requirements as per the quality and sampling plans, including dimensions, visual defects, and coil winding quality.

· Conduct tests on adhesion, paint thickness of primer, top coat and backer, color matching, solvent rub tests, and all other related testing as per quality plan. · Incoming paint, raw material inspection conformance to set requirements as per the quality plan and technical data sheet |

· Full

· Full

· Full |

| Documentation | · Retain and keep product samples on file.

· Record results of inspections and testing in hard copies and enter as soft copies in the system. · Record results of incoming inspection of paint and raw material in hard copies as well as soft copies |

· Full

· Full

· Full |

| Safety and Housekeeping | · Comply with all safety and health procedures of the department.

· Contribute to the development of department and company safety standards and procedures. |

· Supporting

· Supporting |

| Other Functions | · All other necessary functions as may be deemed necessary and assigned by the next level of supervision. | · Supporting |

-

Forward CV’s to recruitment.goodmans@gmail.com

HELPLINE NUMBER: +91-9820020511 / Landline N0: +91-24446677 /11